- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

DLS-LHOP2024071108

C-Laser

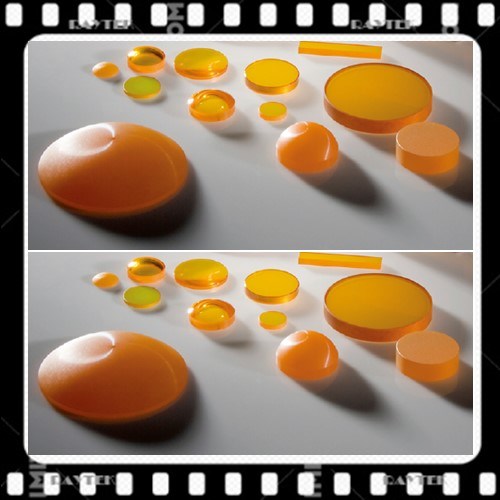

General Introduction: CVD Zinc Selenide

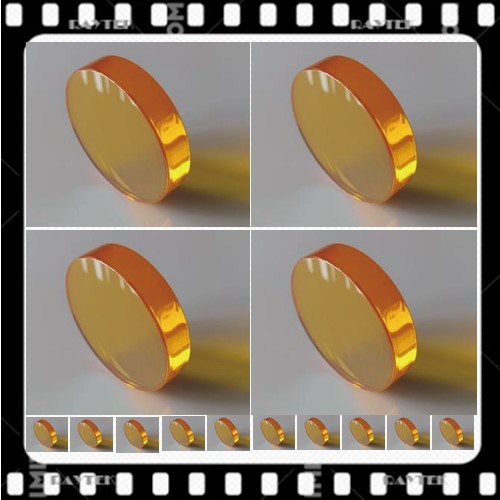

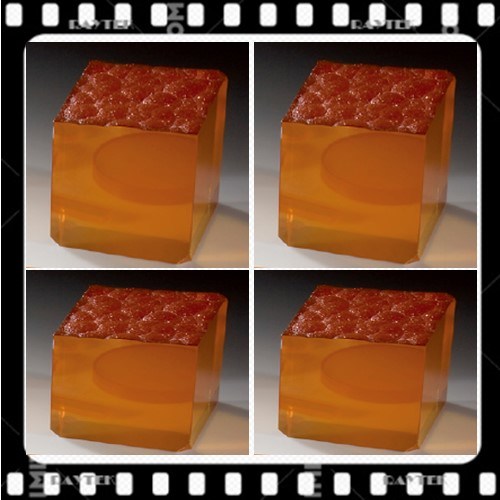

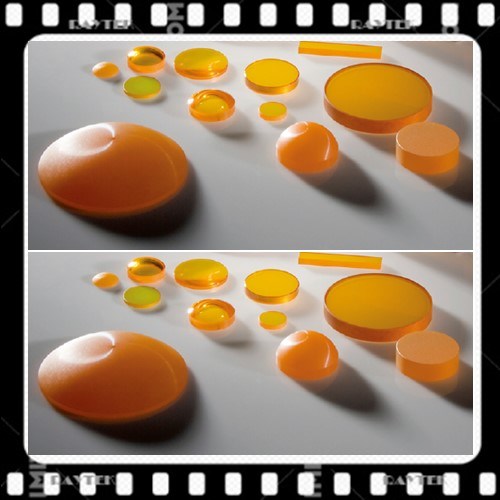

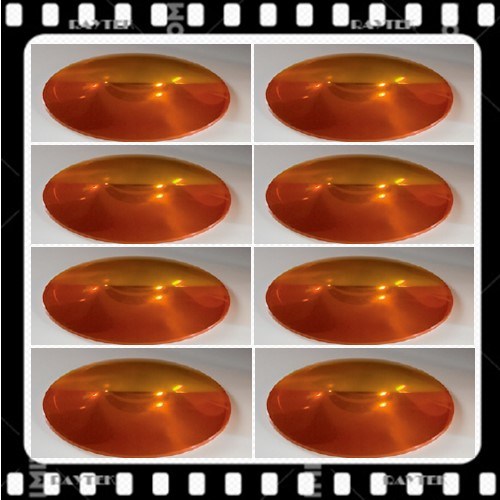

Chemically vapor deposited CVD Zinc Selenide is the material of choice for use as optical components in high powered CO2 lasers due to its low bulk absorption at 10.6 microns. Its index of refraction homogeneity and uniformity offers excellent optical performance for use as protective windows or optical elements in high resolution forward looking (FLIR) thermal imaging equipment. This material has also been used as small windows and lenses in medical and industrial applications, such as thermometry and spectroscopy.

CVD Zinc Selenide is chemically inert, non-hygroscopic, highly pure, theoretically dense and easily machined. It has extremely low bulk losses due to absorption and scatter, has a high resistance to thermal shock and is stable in virtually all environments.

Custom diameters, rectangles, CNC-profiled blanks, generated lens blanks, prisms and near-net shape domes can be made to your specifications.

Products Name: CVD Zinc Selenide

Alias: CVD Zinc Selenide, Zinc Selenide, Hellma Zinc Selenide, Hellma CVD Zinc Selenide, Hellma ZnSe, Hellma ZnSe materials, Hellma ZnSe IR materials, Zinc Selenide IR glass, ZnSe IR glass, ZnSe Optical Widnows, Hellma Zinc Selenide Infrared materials, ZnSe Infrared materials, etc.

, etc.

Main Characteristics:

1).The chemical properties of CVD ZnSe Of Hellma matrials are inert;

2). It has non hygroscopicity and high purity;

3). Very compact and easy to machine;

4). It has good absorption and scattering ability;

5).The volume loss of this material is very low,

6).It has high tolerance to thermal shock;

7).It can maintain its stability under almost all environmental conditions.

8).Round blanks and sheets are available in stock to meet your urgent needs

Thermal Properties:

| Items | Value |

| Coefficient of Thermal Expansion [K-1] @273K 7.1 x 10-6 [K-1] @373K 7.8 x 10-6 [K-1] @473K 8.3 x 10-6 | [K-1] @273K 7.1 x 10-6 [K-1] @373K 7.8 x 10-6 [K-1] @473K 8.3 x 10-6 |

| Thermal conductivity [JK-1m-1s-1] @298K | 18 |

| Heat capacity [Jg-1K-1] @298K | 0.339 |

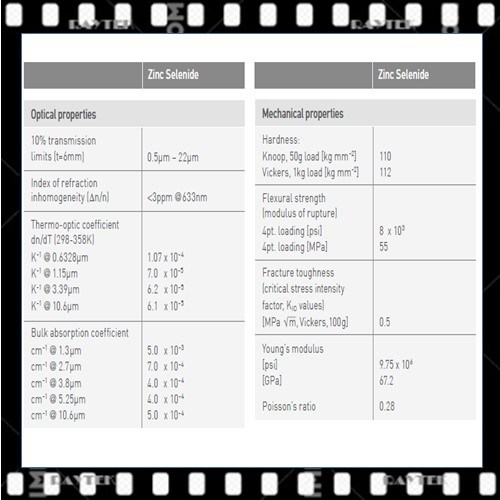

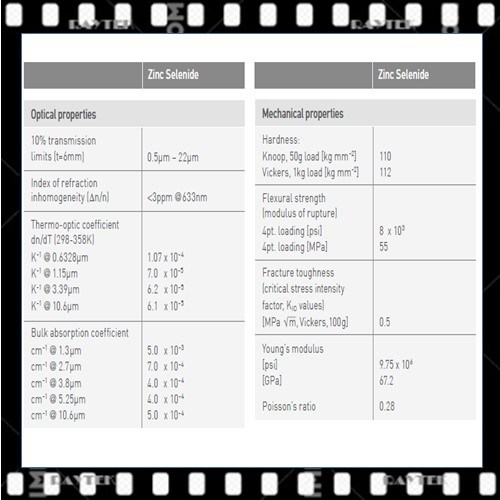

Mechanical Properties:

| Items | Value |

| Hardness: Knoop, 50g load [kg mm-2] 110 Vickers, 1kg load [kg mm-2] | 110 112 |

| Flexural strength (modulus of rupture) 4pt. loading [psi] 4pt. loading [MPa] | 8 x 103 55 |

| Fracture toughness (critical stress intensity factor, KIC values) [MPa m, Vickers, 100g] | 0.5 |

| Posssion's Ration u | 0.343 |

| Young's modulus [psi] [GPa] | 9.75 x 106 67.2 |

| Poisson's ratio | 0.28 |

| Crystal structure | Cubic |

| Grain size | 50-70um |

| Density [g/cm-3] @298K | 5.27 |

| Resistivity [ cm] | ~1012 |

| Chemical purity [%] | 99.9996 |

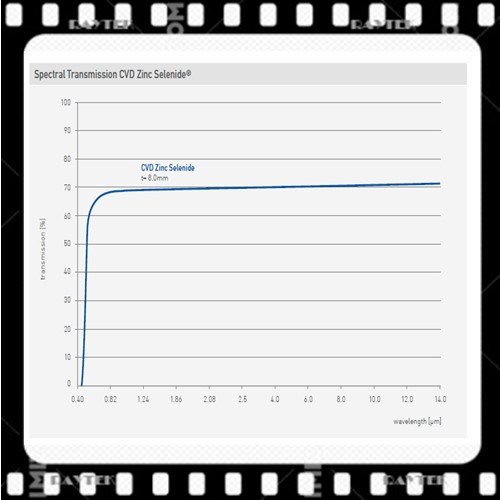

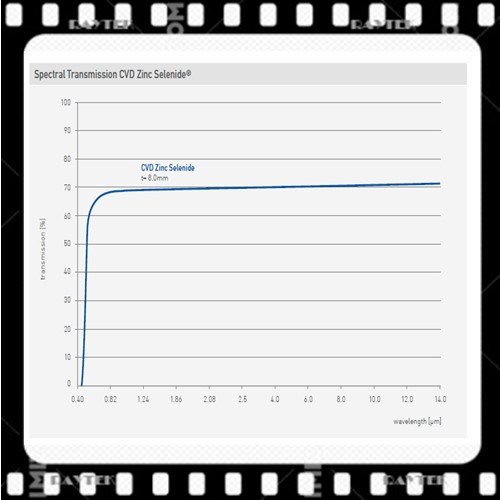

Optical Properties:

| Items | Value |

| 10% transmission limits (t=6mm) | 0.5μm - 22μm |

| Index of refraction inhomogeneity (Dn/n) | <3ppm @633nm |

| Thermo-optic coefficient dn/dT (298-358K) K-1 @ 0.6328μm K-1 @ 1.15μm K-1 @ 3.39μm K-1 @ 10.6μm | 1.07 x 10-4 7.0 x 10-5 6.2 x 10-5 6.1 x 10-5 |

| Bulk absorption coefficient cm-1 @ 1.3μm cm-1 @ 2.7μm cm-1 @ 3.8μm cm-1 @ 5.25μm cm-1 @ 10.6μm | 5.0 x 10-3 7.0 x 10-4 4.0 x 10-4 4.0 x10-4 5.0 x 10-4 |

Main Applying Fields:

| Applying Fields: | 1).High energy CO2 laser system 2).High resolution forward looking infrared (fur) 3).Protection window of thermal imaging equipment 4).Small size windows and lenses for medical and industrial applications, such as thermometers and spectrometers. 5). Evaporation source material |

| ***** |

Matching Custom Manufacturing Serivce:

Including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.

Matching processing equipments;

1).Single side lapping and polishing machines

2).Duble sided polishing machines

3).Ring throwing machines

4).DMG five-axis five-linkage spherical milling machine

5).DMG ultrasonic machining center

6).Super large scale gantry cnc machining center (2.0*2.0m)

7).Super large scale surface grinder (1.6m*1.6m)

8).CNC cutting machines

9).Thin plate cleaning machines

10).Ultrasonic trough cleaning machines

11).Plane interferometers

12).Two dimensional detectors

13).Ion beam polishing machines

14).Magnetorheological polishing equipments

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

General Introduction: CVD Zinc Selenide

Chemically vapor deposited CVD Zinc Selenide is the material of choice for use as optical components in high powered CO2 lasers due to its low bulk absorption at 10.6 microns. Its index of refraction homogeneity and uniformity offers excellent optical performance for use as protective windows or optical elements in high resolution forward looking (FLIR) thermal imaging equipment. This material has also been used as small windows and lenses in medical and industrial applications, such as thermometry and spectroscopy.

CVD Zinc Selenide is chemically inert, non-hygroscopic, highly pure, theoretically dense and easily machined. It has extremely low bulk losses due to absorption and scatter, has a high resistance to thermal shock and is stable in virtually all environments.

Custom diameters, rectangles, CNC-profiled blanks, generated lens blanks, prisms and near-net shape domes can be made to your specifications.

Products Name: CVD Zinc Selenide

Alias: CVD Zinc Selenide, Zinc Selenide, Hellma Zinc Selenide, Hellma CVD Zinc Selenide, Hellma ZnSe, Hellma ZnSe materials, Hellma ZnSe IR materials, Zinc Selenide IR glass, ZnSe IR glass, ZnSe Optical Widnows, Hellma Zinc Selenide Infrared materials, ZnSe Infrared materials, etc.

, etc.

Main Characteristics:

1).The chemical properties of CVD ZnSe Of Hellma matrials are inert;

2). It has non hygroscopicity and high purity;

3). Very compact and easy to machine;

4). It has good absorption and scattering ability;

5).The volume loss of this material is very low,

6).It has high tolerance to thermal shock;

7).It can maintain its stability under almost all environmental conditions.

8).Round blanks and sheets are available in stock to meet your urgent needs

Thermal Properties:

| Items | Value |

| Coefficient of Thermal Expansion [K-1] @273K 7.1 x 10-6 [K-1] @373K 7.8 x 10-6 [K-1] @473K 8.3 x 10-6 | [K-1] @273K 7.1 x 10-6 [K-1] @373K 7.8 x 10-6 [K-1] @473K 8.3 x 10-6 |

| Thermal conductivity [JK-1m-1s-1] @298K | 18 |

| Heat capacity [Jg-1K-1] @298K | 0.339 |

Mechanical Properties:

| Items | Value |

| Hardness: Knoop, 50g load [kg mm-2] 110 Vickers, 1kg load [kg mm-2] | 110 112 |

| Flexural strength (modulus of rupture) 4pt. loading [psi] 4pt. loading [MPa] | 8 x 103 55 |

| Fracture toughness (critical stress intensity factor, KIC values) [MPa m, Vickers, 100g] | 0.5 |

| Posssion's Ration u | 0.343 |

| Young's modulus [psi] [GPa] | 9.75 x 106 67.2 |

| Poisson's ratio | 0.28 |

| Crystal structure | Cubic |

| Grain size | 50-70um |

| Density [g/cm-3] @298K | 5.27 |

| Resistivity [ cm] | ~1012 |

| Chemical purity [%] | 99.9996 |

Optical Properties:

| Items | Value |

| 10% transmission limits (t=6mm) | 0.5μm - 22μm |

| Index of refraction inhomogeneity (Dn/n) | <3ppm @633nm |

| Thermo-optic coefficient dn/dT (298-358K) K-1 @ 0.6328μm K-1 @ 1.15μm K-1 @ 3.39μm K-1 @ 10.6μm | 1.07 x 10-4 7.0 x 10-5 6.2 x 10-5 6.1 x 10-5 |

| Bulk absorption coefficient cm-1 @ 1.3μm cm-1 @ 2.7μm cm-1 @ 3.8μm cm-1 @ 5.25μm cm-1 @ 10.6μm | 5.0 x 10-3 7.0 x 10-4 4.0 x 10-4 4.0 x10-4 5.0 x 10-4 |

Main Applying Fields:

| Applying Fields: | 1).High energy CO2 laser system 2).High resolution forward looking infrared (fur) 3).Protection window of thermal imaging equipment 4).Small size windows and lenses for medical and industrial applications, such as thermometers and spectrometers. 5). Evaporation source material |

| ***** |

Matching Custom Manufacturing Serivce:

Including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.

Matching processing equipments;

1).Single side lapping and polishing machines

2).Duble sided polishing machines

3).Ring throwing machines

4).DMG five-axis five-linkage spherical milling machine

5).DMG ultrasonic machining center

6).Super large scale gantry cnc machining center (2.0*2.0m)

7).Super large scale surface grinder (1.6m*1.6m)

8).CNC cutting machines

9).Thin plate cleaning machines

10).Ultrasonic trough cleaning machines

11).Plane interferometers

12).Two dimensional detectors

13).Ion beam polishing machines

14).Magnetorheological polishing equipments

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.